Dipl.-Ing. Stefan Kuntzagk, Senior Engineer, Numerical Simulation and Performance, Lufthansa Technik, Hamburg

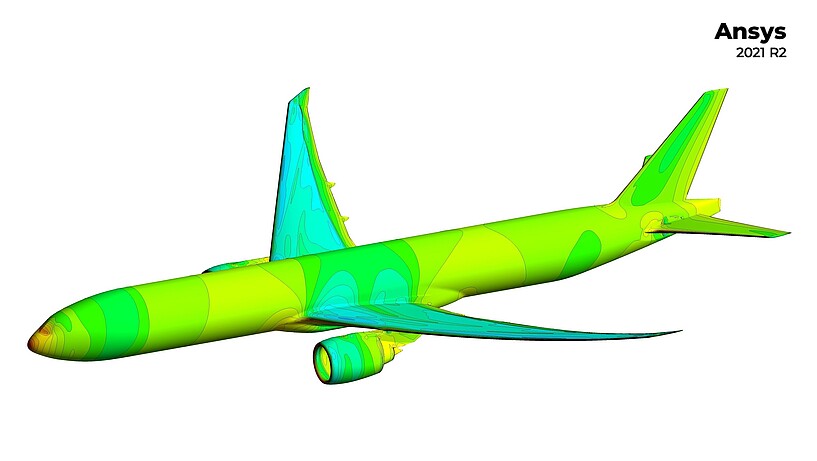

The Aeroshark riblet film imitates the shark skin effect and causes a noticeable drag reduction, which is equivalent to one percent of saved fuel based on a typical long-haul flight. This lecture gives insight into the development of Aeroshark for the Boeing 777 from an aerodynamic perspective. Riblets reduce losses from interaction of microscopic vortices with the wall. This beneficial effect is integrated into the CFD model using extensions of the commercial solver Ansys CFX, which allows the investigation of large-scale models like an entire aircraft. The turbulence model modified for the riblet effect was verified by experimental results from DLR and DNW. Many secondary effects became visible due to changes in the boundary layer thickness when the entire flight envelope was investigated. Hence, for certification, effects on flight characteristics, structural integrity and functionality of aircraft systems had to be considered. Dedicated flight tests for aircraft stability and control were performed with special test programs, because here numerical tools usually show only low confidence. The enhanced fuel saving analysis is based on full flight data in contrast to single snap-shots as in standard aircraft performance monitoring. A problem is the uncertainty in total passenger mass due to the unknown mass of each individual passenger. However, an alternative approach for weight determination has been used, which is based on attitude sensors of the aircraft and reduces the uncertainty of the aircraft weight. This significantly improves the confidence of the drag analysis process.

Weitere Informationen zum Inhalt des Vortrags hier im PDF (Download).

Organisation: RAeS Hamburg in cooperation with the DGLR, VDI, ZAL & HAW

Die Veranstaltung findet ausschließlich in Präsenz statt. Weitere Informationen hier.