'For us, the hybrid test bench is an initial milestone. It took three years to implement it. We have learned a great deal and are now happy that we can familiarise the students with the new drive systems, theoretically and practically,' says Dr. Hanno Ihme-Schramm, professor of combustion engines and thermodynamics. The new test bench means the students are now able, for the first time, to investigate not only a purely combustion engine or an electric drive system, but also a so-called hybrid drive system. This is a combination of a classic combustion engine and an electric drive system.

The drive systems study specialisation is changing

The changes in the sector are also reflected in the courses on the topic: 'We started integrating relevant electrical engineering content into the lectures for the drive systems specialisation five years ago. This means that the material on the combustion engine can't be handled as extensively as before in all areas,' says Ihme-Schramm. The Department of Automotive and Aeronautical Engineering also coordinates with industry on an ongoing basis.

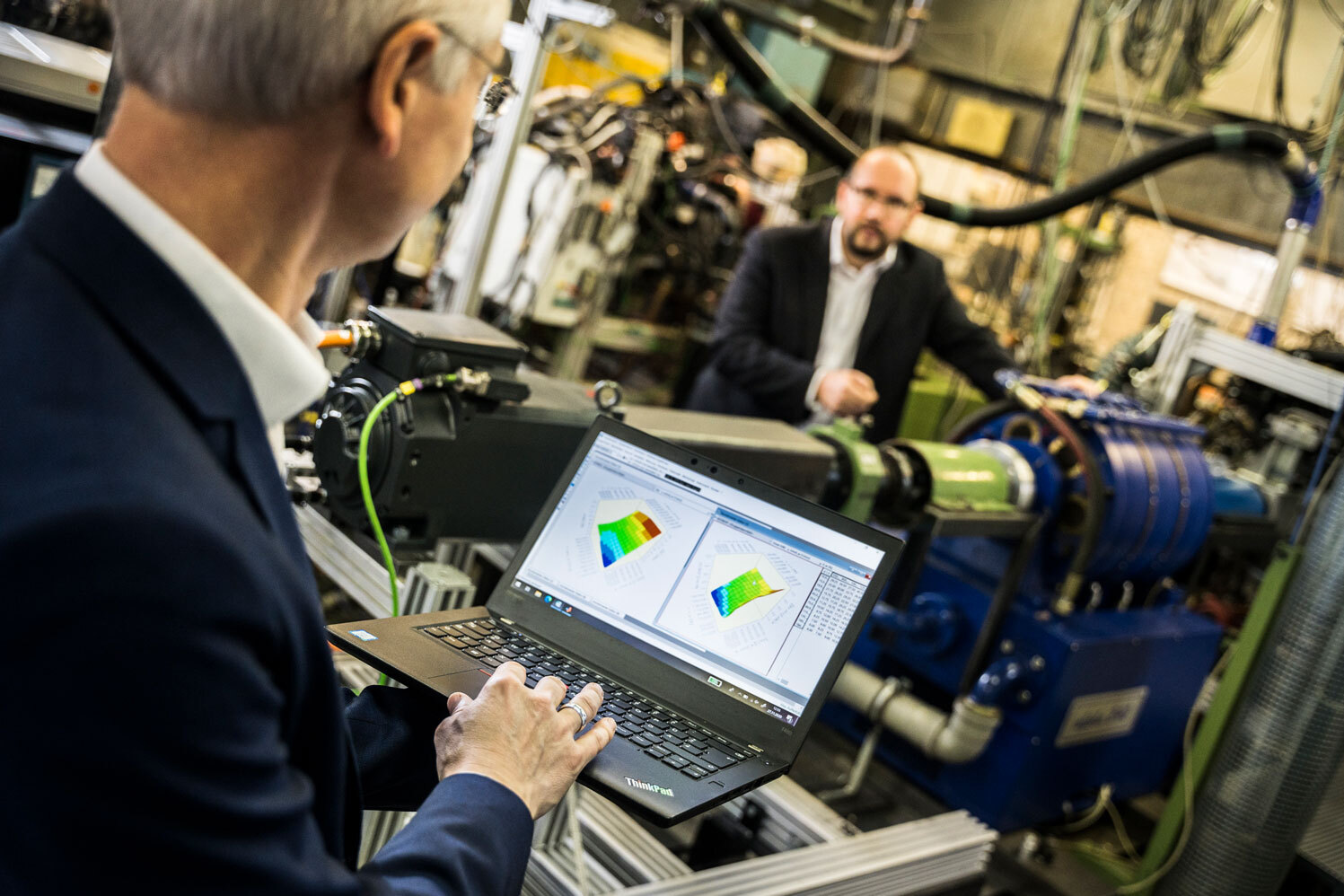

One example of this is the model-based motor application. Prof. Dr.-Ing. Thomas Netzel, professor of measurement and control engineering, explains what this means: 'We create a virtual model of a motor, which is used, for example, to help reduce a vehicle's energy consumption. The necessary methodological knowledge and experience in applying it to optimise such complex systems are taught in our department. In this way we've established a good reputation and strong demand in the automotive industry.'